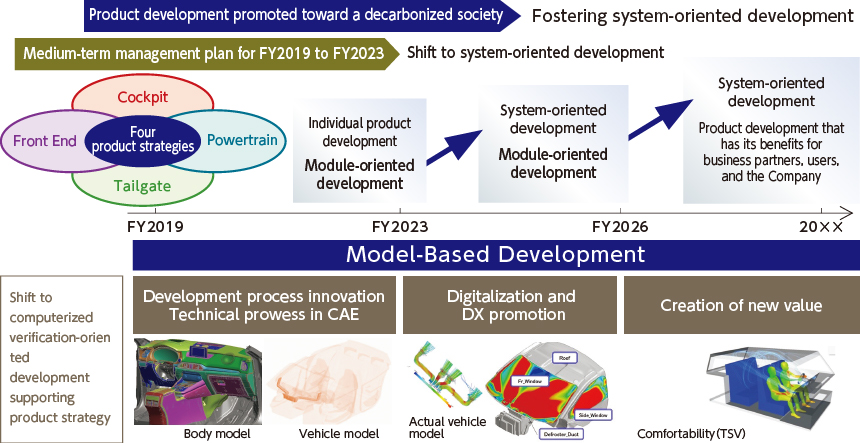

The automotive industry is undergoing a once-in-a-century period of change, such as the progress of CASE- Connected, Autonomous, Shared & Service and Electrification- and the need to meet environmental requirements. Now is the time for DaikyoNishikawa to review its development framework. Until now, the Company’s product strategy has focused on individual product development. Its future product strategy will focus on strengthening module-oriented development and system-oriented development encompassing functional integration with a decarbonized society in mind.

This product strategy is supported by Model-Based Development (MBD). Shifting to computerized-verification-oriented development and promoting digitalization and Digital Transformation (DX), we aim to create new value.

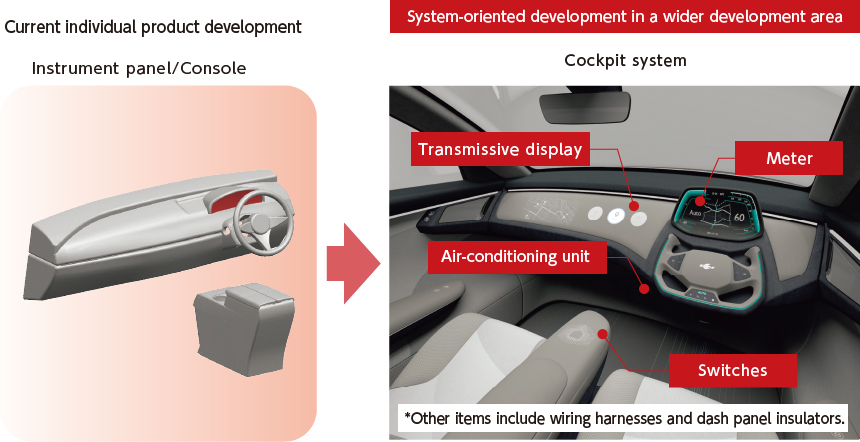

Cockpit Strategy

Aiming for a shift from instrument panels to cockpits, or from individual product development to system-oriented development

(Click to Enlarge)

The shift to vehicle electrification will bring about changes in the required performance and functions, as well as demand for packages differing from those for conventional internal combustion engines. In addition to the instrument panels and consoles that we are currently developing and manufacturing, we will expand our development areas to include displays, meters, and air conditioner units as part of our value chain transformation, with the aim of making system-oriented proposals. In the expanded development area, we will undertake system-oriented development of cockpits, through which we will integrate optimal functions and promote technology internalization, utilizing cutting-edge technology and multi-functional technology. Furthermore, we will develop products that satisfy customers with a consistent texture of interior parts and help build a low-carbon society with overall weight reduction.

To achieve these goals, we are working on optimal development with a focus on electrification.

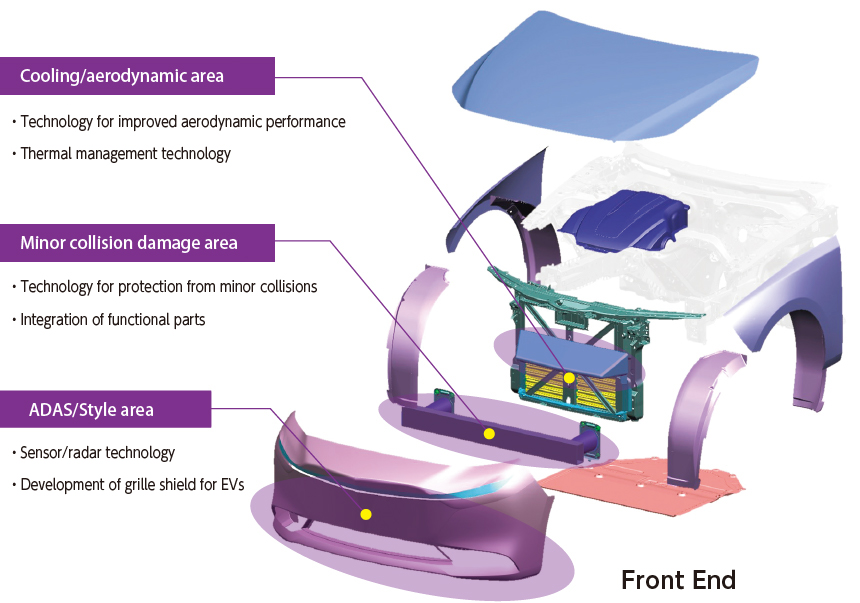

Front End Strategy

Basic functions maximized with an optimal structure for the combination: Aerodynamic management + Advanced Driver Assistance System (ADAS)

(Click to Enlarge)

individual products, in the future, we will improve their cooling and aerodynamic performance, reduce collision damage, and make the ADAS harmonized with the style to contribute to improved energy efficiency, safety, and texture with vehicle electrification in mind.

To achieve these goals, we are focusing on the development of aerodynamic and ADAS parts.

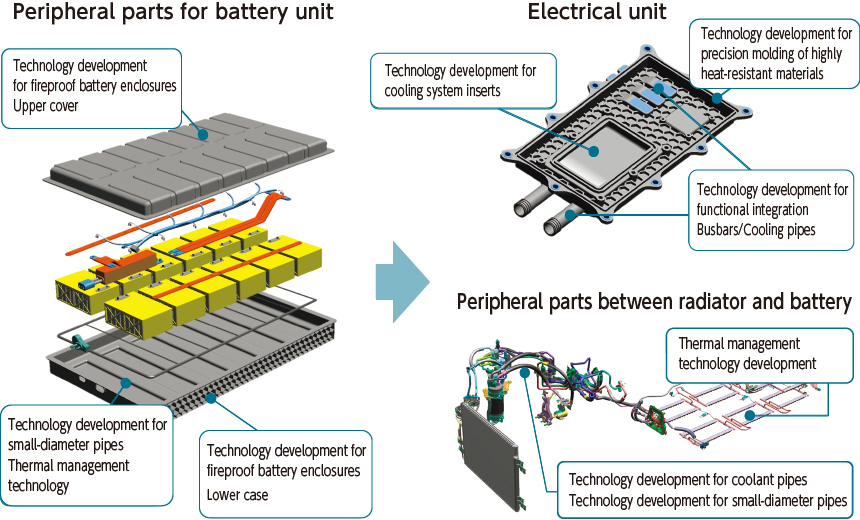

Powertrain Strategy

New technologies combined with existing technologies that we have developed with internal combustion engine-related parts to meet the needs of diversifying electric vehicles

(Click to Enlarge)

The rapid vehicle electrification in step with the recent environmental awareness has a considerable impact on the Company; it is necessary to quickly grasp customer needs in this area and develop new technologies for electrification.

However, needs vary by country and region. We believe it is important to provide products that meet customer expectations accordingly. Meeting the needs of electric vehicles will be a new pillar of our business. For this end we will integrate existing technologies and new technologies and work on commercialization suitable for diversifying electric vehicles.

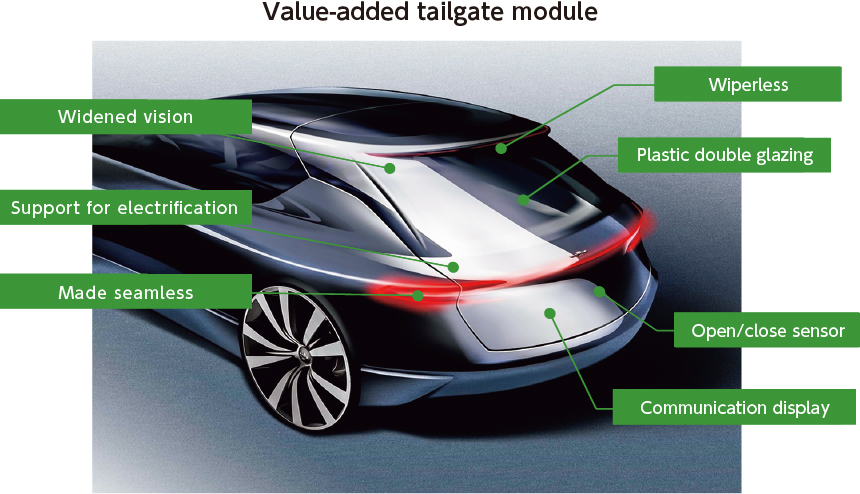

Tailgate Strategy

Development of the lightest tailgate module equipped with high design appeal as well as safety and comfort devices

(Click to Enlarge)

Tailgates are expected to become heavier in the future due to advances in automotive safety technology and CASE, which will necessitate the incorporation of additional functions such as sensors and communication capabilities. Therefore, as the first step, we are addressing the challenge of further, thorough weight and cost reduction of the plastic tailgate. We are working on technology development in all product-related aspects, such as our original in-house plastic materials, the adoption of new structures, and development of paints, as well as innovations in injection molding technology, in adhesion technology, and in the assembly process.

Going forward, we will continue to make new developments while flexibly adapting ourselves to changes in the business environment, to market trends, and to OEM needs, make proposals to automakers, and pursue commercialization.