Synergy between plastics and engineering methods

Engineering development for recycling waste material generated in the manufacturing process

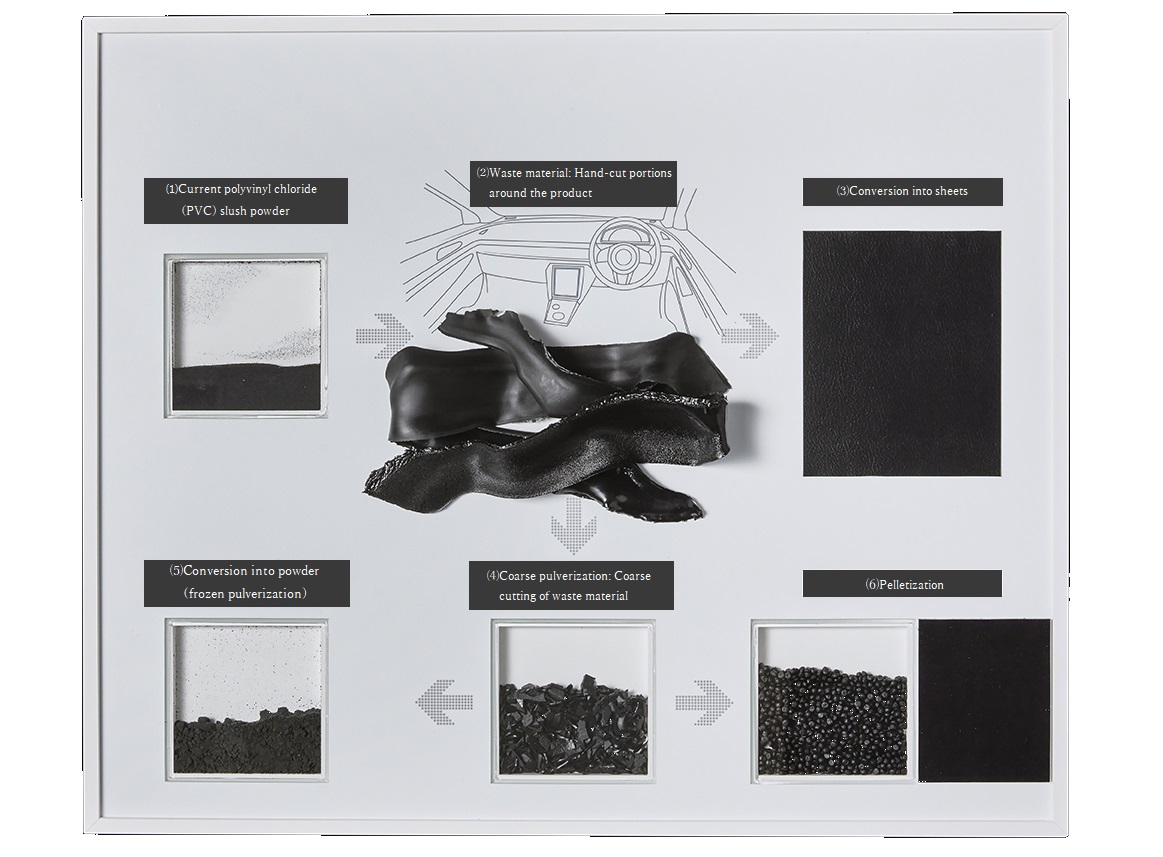

(1) Current polyvinyl chloride (PVC) slush powder

(2) Waste material: Hand-cut portions around the product

(3) Conversion into sheets

(4) Coarse pulverization: Coarse cutting of waste material

(5) Conversion into powder (frozen pulverization)

(6) Pelletization