KEYWORD-01

One-Stop Production System

Monozukuri with a vertically integrated One-Stop Production System

DNC’s Monozukuri providing higher levels of flexibility, cost effectiveness, and quality is made possible by in-house manufacturing encompassing all processes from research and development to production plus quality assurance related thereto, as well as sales and marketing.

That is why DNC can provide products that meet the requirements of its customers and society and meet their expectations for creating new value in mobility.

(Click to Enlarge)

KEYWORD-02

Various Engineering Methods

Commitment to Various Engineering Methods

We have a wide variety of production equipment that maximizes the high technological capabilities that we have cultivated over the years. Using it, we provide all kinds of plastic products, from automotive interior parts to exterior parts, powertrain parts, and housing parts.

We continue to pay close attention to the details of the production process, from product design to molding, painting, and assembly, to ensure safety and quality—the most important features—and to flexibly respond to market demands such as high-mix low-volume production.

Molding

Powder Slush Molding

Painting

Spindle Painting

Assembly

Fully automated assembly robot

Manufacturing

KEYWORD-03

Synergy between Technical Prowess and Creativity Leading to New Possibilities

Synergy between High Technical Prowess and Flexible Creativity to Explore New Possibilities

We have not yet exhausted the potential of the materials known as plastics and of our technology at all.

Since the days when metal was the norm, we at DNC have taken on the challenge of building a wide range of items using plastic, as a comprehensive plastics manufacturer. We will create value that the market has not yet seen and items that have not existed in the world by making full use of the technological capabilities and experience we have cultivated so far, as well as flexible thinking that is not bound by preconceived notions.

Material Development by Blending

We prevent over-specification and reduce the cost by creating the optimal formula in-house that satisfies performance and cost requirements.

Harmonious Combination of Plastic and Electric Parts

DNC also develops electrical parts such as electronic boards.

It responds to market needs with its technology for combining plastic and electrical parts available uniquely from DNC, which has a thorough knowledge of automotive parts.

Design Development

We delineate forms of future automobiles and propose a comfortable space that balances aesthetic design and engineering.

R&D

KEYWORD-04

Co-creation Activity

Co-creating the Future Envisioned by Our Customers

DNC makes co-creation efforts conducting research and design together with automakers.

The phrase “exceed expectations” in the corporate philosophy refers to Monozukuri based on the concept of understanding the customer’s vision of the automobiles they desire to make and providing products that exceed their expectations, rather than the belief that it is sufficient to make parts in accordance with the customer’s specifications.

Through co-creation activities, DNC will continue to give shape to any vision and create products that exceed the expectations of its customers.

KEYWORD-05

Sustainability

Build a Sustainable Society by Our Hands

There are two main approaches to solving social issues with plastics: one is to replace metal with plastics; the other is to modify plastics. In addition, to solve problems that cannot be solved by our company alone through Monozukuri, we will remain committed to creating innovation and revitalizing the local community through industry-academia-government collaboration.

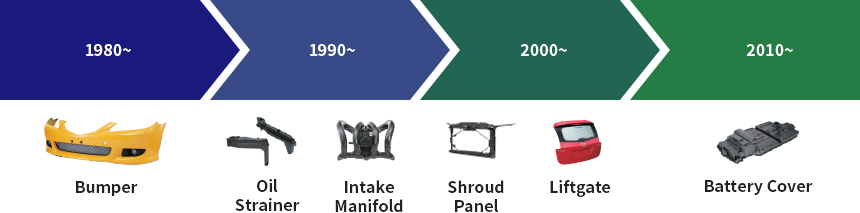

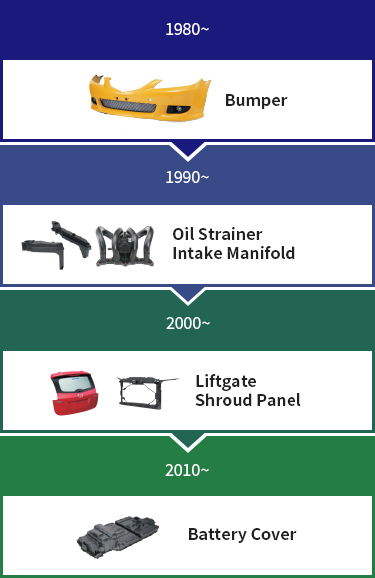

Switching from Metal to Plastics

We have changed numerous production items from metal to plastics. Plastics are advantageous in that they are light, have a high degree of freedom in shape, and provide insulation. Utilizing these advantages, we help reduce CO2 emissions owing to the light weight of plastics and improve aesthetics in design.

Modifying Plastics

To mitigate environmental issues such as CO2 emissions, interest has developed in the use of plastics made from renewable biological resources in place of plastics derived from petroleum. DNC manufactures interior and exterior parts using plant-derived plastics and makes development efforts to expand the range of their use.

Sustainability

KEYWORD-06

Be a Brand of Choice

We will create new possibilities of Monozukuri.

Toward that future, the next challenge we will take on is “developing people.” With employees’ versatile thinking and powerful potential to make steady progress, we will grow together and the future will flourish. And we will change the world’s view of Monozukuri.

Brand Concept

Making our tomorrow

Corporate philosophy / DNC brand