Policy/Concept

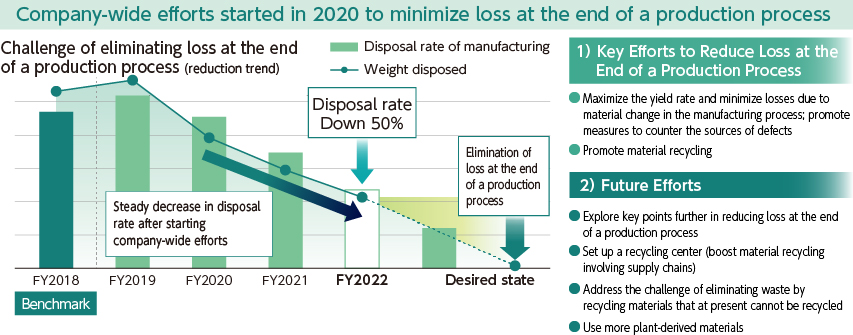

We formed a cross-functional team consisting of all departments involved in Monozukuri to eliminate losses due to plastic waste at the end of a production process. The team holds Materials Loss Reduction Committee meetings monthly and leads company-wide efforts toward building a recycling-oriented society. Its activities include promotion of efforts to reduce loss at the end of a production process and furthering of material recycling.

Key Efforts to Reduce Loss at the End of a Production Process

- Maximize the yield rate and minimize losses due to material change in the manufacturing process; promote measures to counter the sources of defects

- Promote material recycling

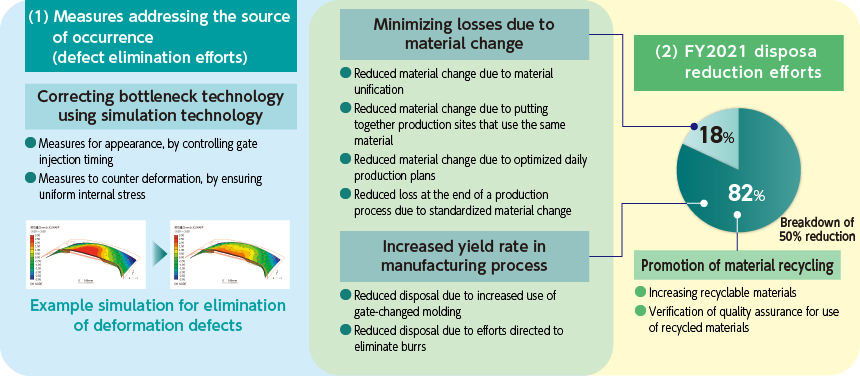

To counter the sources of loss at the end of a production process, we strive to eliminate defects by clarifying the mechanism behind the occurrence of defects and developing measures through simulation technology. In addition, measures used to minimize losses resulting from set-up change include standardizing material changes and promoting material unification. Moreover, to raise the yield rate in the manufacturing process and promote material recycling, we strive to use more recyclable materials, verifying the use of recycled materials as to product performance and quality.

Future Efforts

- Explore key points further in reducing loss at the end of a production process

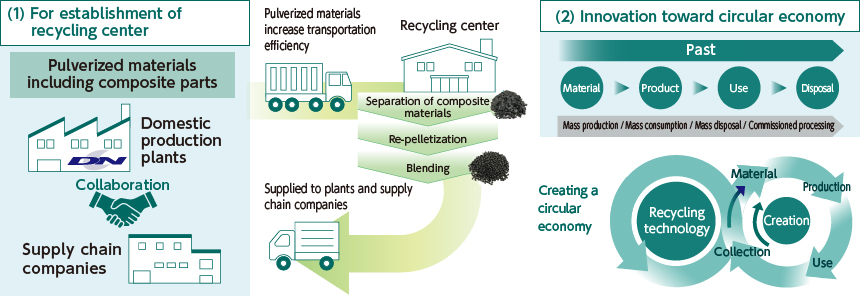

- Set up a recycling center (boost material recycling involving supply chains)

- Address the challenge of eliminating waste by recycling materials that at present cannot be recycled

- Use more plant-derived materials

One major challenge to eliminating loss at the end of a production process is the recycling of composite materials including painted products. We are working on development of technology to separate these composite materials and on establishment of a recycling center equipped with that technology. Furthermore, for a circular economy that deals with products collected from the market, we will be geared toward material recycling, utilizing composite material separation and material blending technologies, with the recycling center playing a leading role.